Connector Systems for the Extreme Demands of Oil & Gas Sector Environments

Downhole high temperature proof

Genalog's combined experience of over 300 years in bespoke and standard high reliability, high shock and vibration and most importantly, high temperature connector systems allows us to "talk technical" for every angle of your Oil and Gas project. Here are some examples from our franchises.

Omnetics Micro & Nano, D-Type, Circular and Strip style Connector solutions

Connectors are placed in harsh and extreme environments in Petroleum applications. Omnetics knows that connectors must be built to meet these demands. They have vigorously tested their connector solutions to make sure that they can provide ruggedness and superiority to meet the demands in this field.

260°C rated Micro-D available to meet your high temperature solutions needs.

Nano – Rectangular Design @ .025” Pitch

Materials: For up to +200°C operation*

Insulator:2 Row-LCP / 30% glass,1 Row-PPS / 40% glass

Epoxy: High Temperature

Pin count: @ .025” pitch – up to 60 positions

Density: Single row or 2 Row

Board Mounting: SMT or Thru-Hole

Current Rating: Up to 1 amp

Vibration: 20G 10-2,000 Hz Detection >10 Nano second

Shock: 100g Detection >10 Nano Second

High Shock Mounting & Mating Hardware

Micro – Rectangular Design @ .050” Pitch

Materials: For up to +200°C operation*

Insulator: PPS / 40% glass

Epoxy: High Temperature

Pin count: @ .050” pitch – up to 97 positions

Density: Single row or 2 Row

Board Mounting: SMT or Thru-Hole

Current Rating: Up to 3 amp

Vibration: 20G 10-2,000 Hz Detection >1 microsecond

Shock: 50g Detection > 1 microSecond

High Shock Mounting & Mating Hardware

Metal Circular Connector Series

(Micro & Nano Available)

High Temperature to +200°C*

Threaded Coupling Mate - Unmate

EMI Cable Shield to Shell Design

Pin Count Micro - up to 27 positions

Pin Count Nano - up to 28 positions

O-ring Sealed

Custom cable design for Petroleum Electronics.

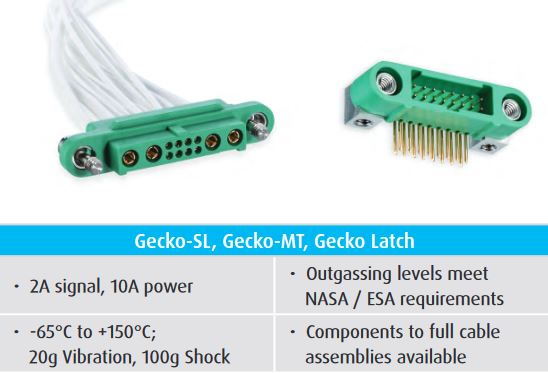

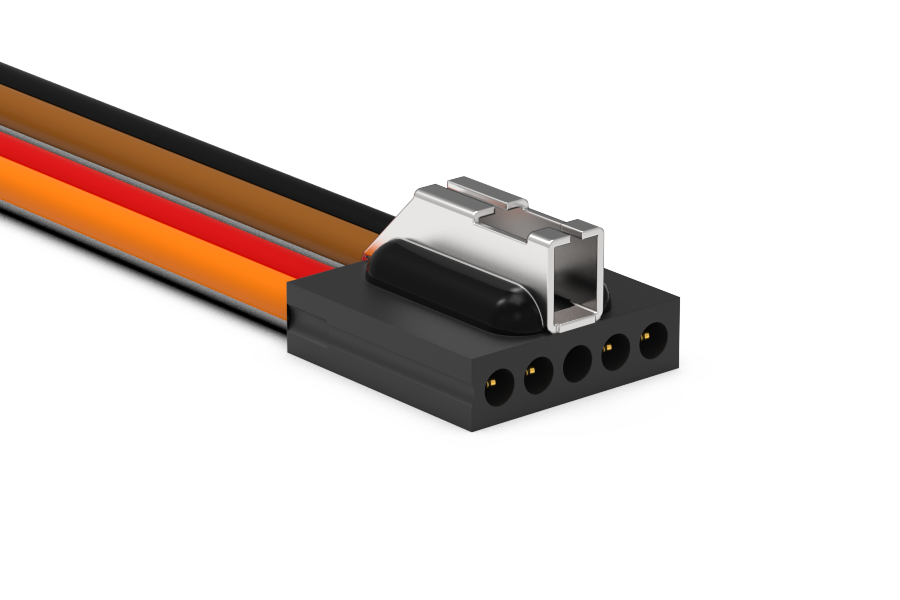

Harwin's range of Durable Industrial Connectors

Whether your energy industry is in the traditional Oil and Gas sector, or the newer sustainable energy market, Harwin has connector products and PCB hardware suitable for all energy creation and distribution equipment.

Harwin are certified to EN9100D / AS9100D, which means continuous improvement in all our quality and systems management, and continuous monitoring of the high quality level maintained across the company and products. This perfectly aligns with the needs of one of the most in-demand industries on our planet. Rugged products from Harwin can provide connector solutions when the environment is a factor: vibration & shock severity, high temperature and humidity.